By Evoqua India

Overview:

Replacing the conventional DI water system with Evoqua’s CEDI technology helps conserve water and reduces operation downtime.

Customer:

Lakhi Ram Lube Control – Manufacturer of Automotive engine oil, Patalganga, Maharashtra, India

Challenge:

With conventional DI (Deionization) system the major challenges were inconsistent water quality and constant system break-in time for resins regeneration process, and thus increasing the plant downtime period and operational cost.

The Key to Success:

Good Customer relationship, huge installed base, and presence of local sales/technical support from Evoqua.

Applications: Manufacturer of Automotive Engine Oil

Markets: Automotive Industry

Our Solution:

Ionpure® CEDI model

Main Page Contents:

Since 1992, Lakhi Ram Lube Control Pvt. Ltd. has been a leading manufacturer and supplier of diesel exhaust fluid, intermediate bulk containers, engine oils, gear oils, etc. The company is well known in the automotive industry for its top-notch quality, services, on-time delivery, and contributions to water conservation and waste management initiatives.

Challenge:

Lakhi Ram Lube Control Pvt. Ltd. operates their manufacturing plant 24/7. It treats the municipal water supply by using conventional DI water systems to generate product water of the required capacity within a 20 hr cycle.

The plant needed to fulfill the increasing demand for constant high-purity water throughout the operation and reduce downtime. In conventional DI system treatment, ion exchange resin regeneration is necessary for recovering exhausted resins. This requires periodic break-in time, which affects plant operations. With their current low-capacity DI water systems, the facility could not meet the increased demand. Also, the wastewater from the regeneration process was high in pH and alkaline value and needed to be neutralized in a separate effluent treatment plant (ETP) with chemicals like NaOH and HCI before it was discharged.

The untreated wastewater discharged resulted in irreversible repercussions to the environment and local community. Hence, the customer sought an alternative technology that would provide consistent water quality, reduce break-in time, and require less chemical consumption.

Solutions:

Lakhi Ram Lube Control Pvt. Ltd. reached out to Evoqua Water Technologies to supply a solution due to our technology reputation and large install base in India. After assessing the client’s current situation, our team recommended the chemical sanitizable Ionpure® CEDI LXM30Z modules to replace the conventional DI technology they were currently using. This solution would help solve their current issues and fit within their budget, meeting ROI requirements.

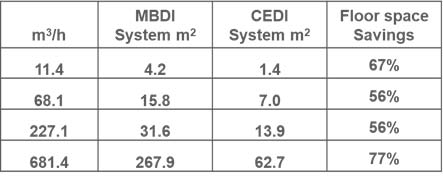

Our CEDI technology provides a one-step process for producing high-quality deionized water with a self-regenerating system that reduces the need for chemicals. The system generates 160 KL of deionized water per day, providing consistent quality throughout the operation. In addition, the system has a smaller footprint, user-friendly operating system, and requires no extra manpower. Below is the comparison sheet of DI and CEDI technology on space saving.

Result:

Our technology has helped Lakhi Ram Lube Control Pvt. Ltd. maintain product quality, enhance its brand image, and reduce operational costs and production downtime with less chemical consumption. After one year of commissioning the project, the client has been satisfied with the Ionpure® CEDI system.

About the Company

Lakhi Ram Lube Control Pvt. Ltd. is one of the leading manufacturer and supplier of automotive engine oil to major OEM’s, Distributors, dealers and stockiest, for automotive engine oil. This engine oil prevents friction in the engine, protect the engine from rusting, keep the pistons cool, and protect engine oil from combustion gases. Established in the year 1992, Lakhi Ram has been a known name in its field for its top-notch product quality, services and on time delivery. The main product they manufacture are Diesel exhaust fluid, Intermediate bulk container, engine oils, gear oil, etc. This industry strives to produce environmentally friendly products for automotive industry with 24 hrs. operational plant to serve the customer without delay. The firm has been major contributors to many sustainability initiatives and water conservation and waste management.

Evoqua Water technologies is a leading provider of water and wastewater treatment solutions, offering a broad portfolio of products, services and expertise to support industrial, municipal, and recreational Customers and helps customers protect and improve the most fundamental natural resource: Water, Evoqua has more then 100 year heritage of innovation and industry firsts, market leading expertise and unmatched customer service where continue to transform water and wastewater. We help more than 38,000 customers and 200,000 installations worldwide and operate in more then 160 locations across 10 countries. Please contact for any enquiries :

Email id : sales.in@evoqua.com | Mobile No. : +91-9566160308